Effectively managing pipe inventory is a complex balancing act for warehouses and industrial facilities. With limited floor space and the daily demands of machinery upkeep, construction schedules, and client orders, disorganized excess pipe storage can grind operations to a halt.

By implementing specialized storage solutions tailored to pipes and tubes, managers can transform cluttered stockrooms into streamlined systems. The right storage plan conquers chaos through durability, flexibility, and space optimization.

Overflowing Unsorted Pipe Inventory

For companies utilizing pipes daily across projects, lacking organization quickly cascades into substantial business disruptions. Without designated pipe storage infrastructure, warehouses often become makeshift dumping grounds for excess inventory and leftovers after installs.

Issues Caused by Disorganized Pipes

Pipes strewn haphazardly occupy premium real estate within warehouses they don’t need. This prevents utilizing the space more effectively for active projects. Workers must navigate literal logjams slowing down pulling inventory for jobs. Pipe damage also increases without proper storage methods.

Consequences of Lacking Organization

Operation leaders universally agree disarray severely diminishes productivity. Congested aisles make locating and pulling inventory incredibly time-consuming. Misplaced pipes also lead to unnecessary reorders when stock already exists onsite. This bloats expenses and project timelines.

Frustrations of Warehouse Managers

For those directing daily warehouse activities, unmanaged inventory triggers limitless headaches. Their responsibility covers monitoring stock levels, safeguarding assets, dispatching items for use, and maximizing space. Cluttered pipes fail on all metrics creating universal frustration.

Specialized Storage Racks Provide Answers

Purpose of Optimized Pipe Storage

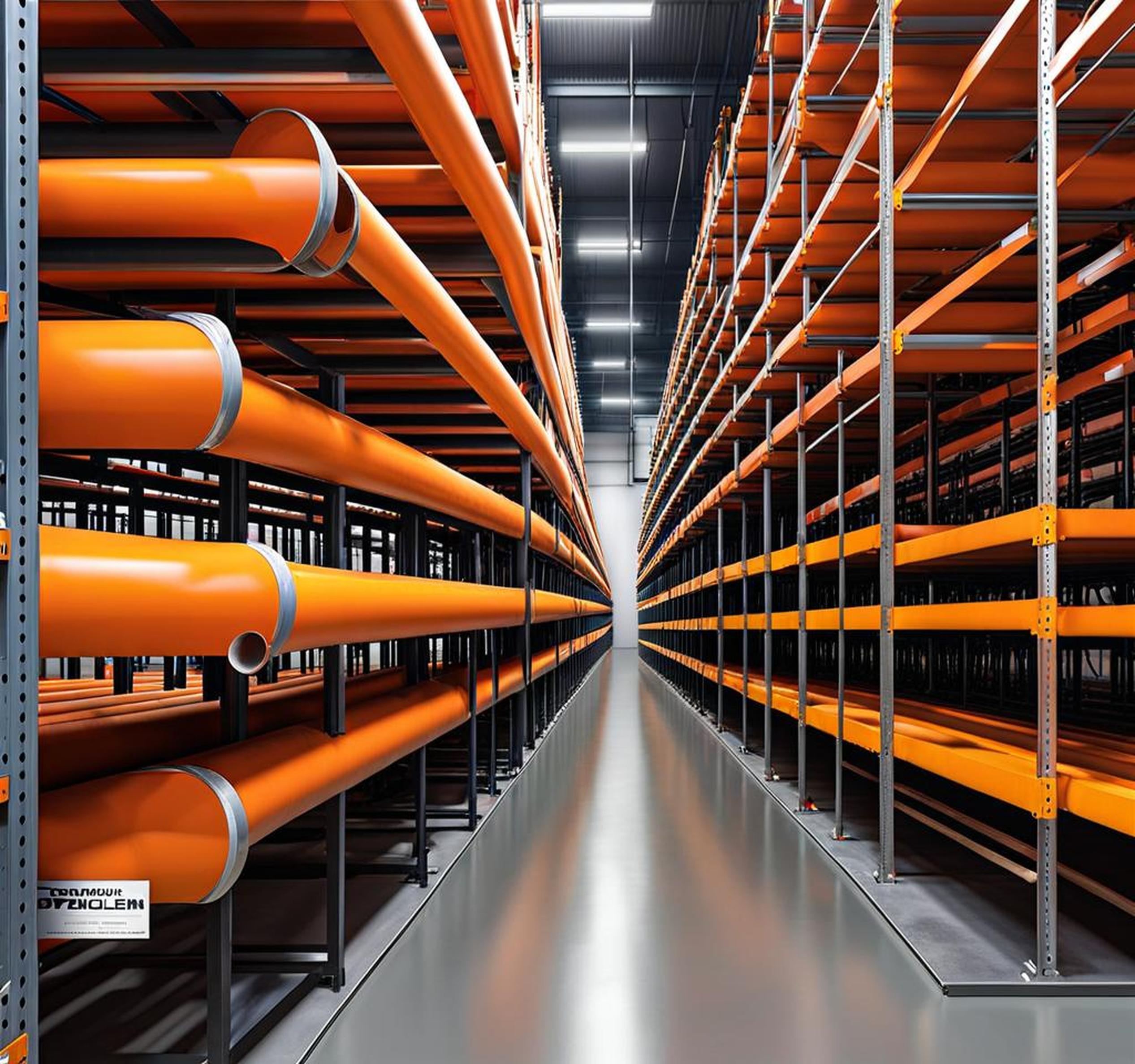

Installing specialized racks creates a centralized storage location ideal for the shape, weight, and handling requirements of pipes. Racks elevate pipes off the floor and compartmentalize them by size. This organization system also protects pipe integrity and provides quick access when needed on the job.

Benefits of an Effective System

The universal advantage of purpose-built pipe racks is liberating usable space previously cluttered with disarray. Warehouse teams also praise increased accuracy of inventory counts and condition assessments. Overall, the cost savings from optimizing operations add up substantially over time.

Types of Storage Racks to Consider

When researching storage options, consider heavy-duty shelving units with adjustable shelves, slotted angles, and removable partitions. Freestanding and wall-mounted models provide versatility for layouts. Mobile racks with casters deliver flexibility as well.

Key Design Factors for Pipe Racks

Durability is Essential

The paramount concern when evaluating pipe storage solutions centers on durability. Pipes often weigh hundreds of pounds each depending on industry and material. Under constant strain, weaker racks will buckle, risking worker safety and product loss. Prioritizing strength enables racks to endure years of use.

Choosing Durable Building Materials

For elementary construction materials, steel and aluminum both allow custom sizing and reputations for stability. Steel provides unmatched raw strength capable of holding thousands of pounds per shelf. Aluminum offers lighter weight for mobility while remaining corrosion-resistant in tough warehouse conditions.

- Steel: Superior strength and load capacity

- Aluminum: Lightweight yet extremely sturdy

- Gauge ratings indicate thickness/durability

Flexibility and Modularity

Warehouses rarely deal with completely standardized pipes single-source. To adapt to fluid inventory, racks should allow easy reconfiguration as needs change. Opting for modular components or mobile units enables facilities to modify layouts responding to new space constraints or pipe dimensions.

Accessibility and Visibility

Quickly locating necessary pipe sizes for project orders equals top priority. Open shelves provide direct access from multiple sides without barricades hindering visibility. Aisles must remain clear for maneuvering carts and lifts during retrieval. Dedicated end-of-row access points speed up overall velocity handling pipes.

Space-Saving Racks Optimize Density

Vertical Storage Model

The sheer scale of many pipe dimension restrains storage solely to ground floor space. Exceeding these boundaries risks overwhelming weight capacities. Utilizing pipe racks allows smart exploitation of vertical real estate. Compartments segment pipes standing on end rather than strewn horizontal.

Planning Your Layout

Precisely estimating current inventory and near-future usage enables accurate rack sizing during installation. This prevents wasted expense overbuilding racks. Proper spacing between aisles and perimeter walls is equally important for safe retrieval/restocking. Poor planning wastes money and nullifies organization benefits.

Implementing Your Pipe Storage Solution

Professional Installation

Given piping’s scale and weight, specialized equipment is mandatory for positioning racks. Factory-certified teams possess intimate knowledge constructing customized rack solutions specific to the space while meeting safety codes.

Performing Regular Inspections

Routine examinations checking for dents, faults, or loose components help nip potential problems. Early detection allows facilities to reinforce issues through joint tightening, bracing additions, preventing irreparable catastrophe before it occurs.

Streamlining pipe inventory starts by honestly assessing current inefficiencies and growth opportunities. Purpose-built storage racks provide the scaffolding for true optimization. Durable customizable solutions reinforce operations today while adapting to tomorrow’s needs.

Utilize Pipe Rack Systems with Integrated Storage Solutions

In addition to holding pipes and tubing, some pipe rack systems now offer built-in storage solutions such as shelves, hooks, and drawers. This allows for efficient organization of smaller tools, parts, and accessories, freeing up valuable floor space and improving overall workplace efficiency.

Consider the Use of Adjustable Pipe Racks

Adjustable pipe racks offer greater flexibility in terms of pipe and tube diameters, lengths, and weights. This is especially important in industries such as plumbing and electrical where a wide variety of pipes and tubes are used. Adjustable racks also make it easier to accommodate new or additional piping systems as they are installed.

Incorporate Lighting into Pipe Rack Systems

Proper lighting is essential for ensuring a safe and efficient work environment, particularly in warehouses and storage areas where pipes and tubes may be difficult to see or locate. By integrating lighting into pipe rack systems, workers can easily locate the pipes and tubes they need, reducing the risk of accidents and improving overall workplace safety.

Modular pipe rack systems offer enhanced customization and flexibility. Rack sections can be easily added, removed, or adjusted to optimize storage space. As inventory needs evolve, more racks can be integrated, changed out, and adapted.