Dealing with a leak under the kitchen sink can be a messy, frustrating experience. However, it is usually not difficult to troubleshoot the cause of the leak and fix it with a little DIY plumbing know-how. We will also cover the most common causes of leaks as well as how to fix them. With the right preparation and safety measures, you can tackle this annoying kitchen plumbing problem yourself!

Signs That Indicate Your Sink’s Supply Lines Are Leaking

There are a few clear signs of leaky water supply lines under a kitchen sink. These include:

- Water pooling under the sink or in the cabinet

- Visible water dripping from fittings or joints

- Dampness or moisture around pipes

- A sudden loss of water pressure at sinks or appliances

- An abnormally high water usage on your utility bill

If you notice any of these, it likely indicates a leak from the hot and cold water supply lines or related components. Catching a kitchen sink leak early on will let you fix it before any significant water damage occurs.

Safety Tips When Inspecting For Leaks

Checking under an active kitchen sink for leaks can expose you to hot water, sharp edges, or chemicals. To stay safe:

- Always turn off the hot and cold water supply valves before starting your inspection

- Wear safety goggles and gloves to protect your eyes and skin

- Keep a bucket or pan ready to catch water that may seep from connections

- Watch for hazards like cleaners, garbage disposals, or broken glass

- Plug the sink and close the drain to prevent small parts from falling down

Taking a minute to prepare a safe inspection area will protect you during the troubleshooting process.

How to Locate the Exact Source of any Sink Supply Line Leaks

To find the origin point of the leak:

- Turn off the hot and cold water supply valves completely

- Remove everything under your sink so fittings are exposed

- Check beneath the sink cabinet for water pooling or moisture

- Scan all water line fittings and connections visually

- Note any corrosion, gaps, cracks or drips

- Follow any water trails back to their highest point

The uppermost point of moisture or a visible drip usually marks the starting location of the leak. Thoroughly tracing water trails from sinks, hoses, supply lines, P-traps and drain pipes will reveal the leak source. Once you’ve found the specific component or connection causing trouble, you can assess the repairs needed.

Common Kitchen Sink Supply Line Connection Points to Check

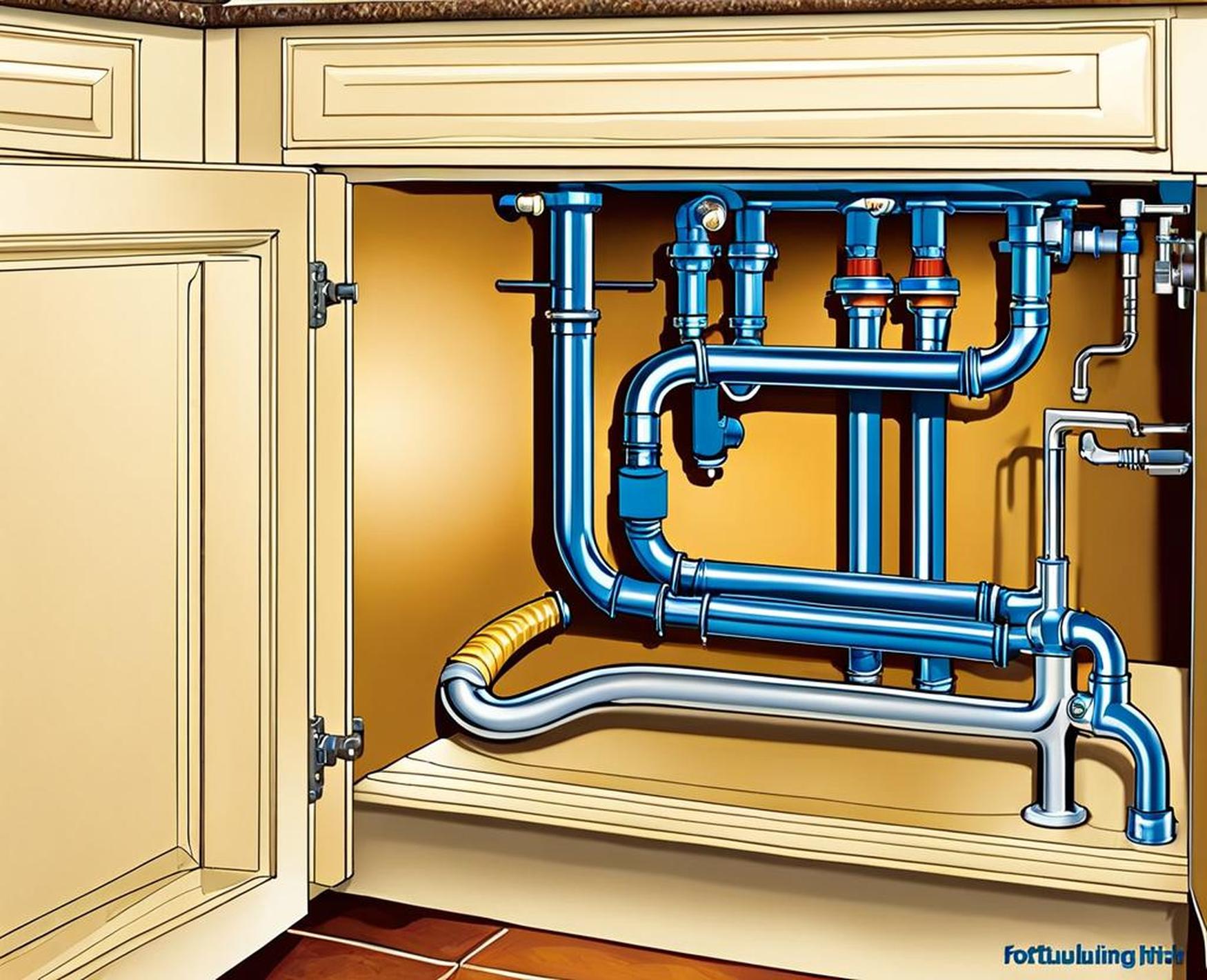

Focus your inspection on supply line joints and connections like:

- Compression fittings attaching valves to supply tubes

- Thicker braided stainless steel sections bending to connect faucets

- Brass connections joining supply pipes to faucet shanks

- Plastic or copper piping connecting valves to main water lines

- Rubber, nylon or metal washers sealing joints

Issues with seals, loose fittings, or cracks in these areas frequently lead to leaks under kitchen sinks.

Reasons for Hot and Cold Water Line Leaks Under Your Sink

Once you’ve found the leak location, figuring out the reason for the problem is next. Let’s review some top causes of leaky supply lines.

1. Old or Corroded Lines

The most common supply line issue is wear and tear from years of use. Signs include:

- Visible corrosion or degradation on older metal pipes

- Cracks or material breakdown in the outer stainless steel tubing of newer lines

- Interior tube cracks within supply lines are also common, causing unseen gradual leaks

Any tiny breach in the lines can lead to water spraying or dripping out. Replacing deteriorated supply lines usually solves leaks quickly.

2. Loose Fittings and Joints

Even when your supply lines seem fine, connections can loosen over time. You may notice:

- Fittings, nuts or clamps that wiggle or spin freely when grasped

- Mini jets of water spraying from joints when the faucet runs

- Visible gaps or deformation in connection points

Constant vibrations from water usage and waste lines can disturb sealed joints. Correctly tightening hardware, using thread tape or resealing gaps often remedies leaks at fittings and unions.

3. Worn Out Rubber Seals and Washers

Hardware like rubber seals, nylon washers and flexible valve seats take constant abuse from water flow. Eventually, they degrade. You may observe:

- Hard water scale, mineral deposits or debris damaging washers

- Cracked, torn, or flattened rubber sealing materials

- Swollen or bent nylon rings around valve ports

Replacing worn out seals and washers restores a secure join. Carefully inspecting all washers at fittings during a repair helps avoid repeated leaks down the road.

4. Improper Water Line Installation

Even new supply lines can leak if mistakes occur during sinking installs. Flaws like:

- Not tightening hardware sufficiently

- Failing to seal threaded joint tape fully

- Misaligned pipe connections causing strain and gaps

lead to small drips. Being methodical about proper positioning, torque levels, sealing, and support prevents installation errors.

Methods for Permanently Repairing Leaky Supply Line Issues

Once you determine the cause, fixing kitchen sink supply line leaks involves:

- Turning off the water supply valves

- Draining any residual water from the sink plumbing

- Disconnecting defective parts or sections

- Assessing any damage and gathering replacement items

- Installing new hardware or lines

- Restoring water flow

- Confirming all joints and seals are leak-free

We’ll outline common solutions for specific leak problems next.

Replacing Old or Damaged Water Supply Lines

For visibly cracked or degrading lines, replacing the entire supply is best. It involves:

- Shutting off hot and cold water valves

- Unscrewing bad supply lines at all endpoints and removing

- Measuring and cutting new stainless braided water lines

- Securing them tightly at valves and faucet ends

- Restoring water flow

- Monitoring for several days to confirm no new leaks form

New supply kits with all washers included make swaps cleaner. Regular replacements maintain reliability.

Tightening Loose Water Line Connections

For simple loose fitting leaks:

- Shut off the water as usual

- Take apart the leaky compression union, threaded joint or clamp

- Inspect and clean seating surfaces thoroughly

- Apply fresh thread-sealing tape for slip joints

- Reconnect the hardware at the proper torque

Snugging hardware defeats vibration and binding issues over time. Occasionally tightening your sink’s supply line connectors prevents leaks.

Replacing Defective Washers and Seals

Faulty seals or washers require:

- Locating the compromised seal/washer

- Assessing if just the seal needs replacing or the entire fitting

- Disconnecting the fitting and removing it if needed

- Gathering identical replacement washers/fittings

- Installing the new seal or component correctly

Carefully examining all washers and seals during repairs means fewer future leaks. Keep spares on hand too.

Correcting Supply Line Installation Mistakes

Fixing poor line connections involves:

- Reviewing the initial install method if possible

- Taking apart all hardware

- Ensuring pipe alignments meet standards

- Applying adequate sealing tape and compounds

- Meticulously tightening all joints as specified

Thoughtful installation practices prevent leaks. Seek assistance if complex connectors or soldering arise.

Tips to Stop Future Leaks Before They Start

Along with repairs, consider these proactive measures:

- Always use quality braided stainless lines and fittings

- Inspect water lines annually for wear

- Replace any supply hoses over 5 years old

- Ensure lines have some slack for valve movement

- Periodically check joint tightness

- Upgrade older multi-bend connectors

Investing in sturdy parts and periodically checking fittings saves you future leakage issues under the sink. Catching problems early keeps plumbing humming.

Calling In a Professional Plumber

While many supply line leaks are DIY-friendly, it’s smart knowing when to call a pro. If you encounter:

- Inability to locate the leak source

- Drips coming from walls, floors or deep under cabinets

- Pipes requiring major modifications or replacements

- Valve and pipe connections in awkward, confined spaces

a qualified plumber has the tools, skills and experience to remedy it correctly. Trust an expert rather than hope a patch fix will last when extensive repairs loom.

Equipped with some basic plumbing troubleshooting skills, you can now assess hot and cold water supply line leaks under your kitchen sink. Simply trace moisture back to its highest point, diagnose what component failed, then implement the matching fix discussed here. As long as no major repiping lurks behind walls, most homeowners can tackle minor supply line leaks using mindful installation methods for reliable results. But when extensive disassembly or modifications become necessary, calling a professional ensures proper corrections. Follow these guidelines and you can handle the most common causes of this pesky issue!