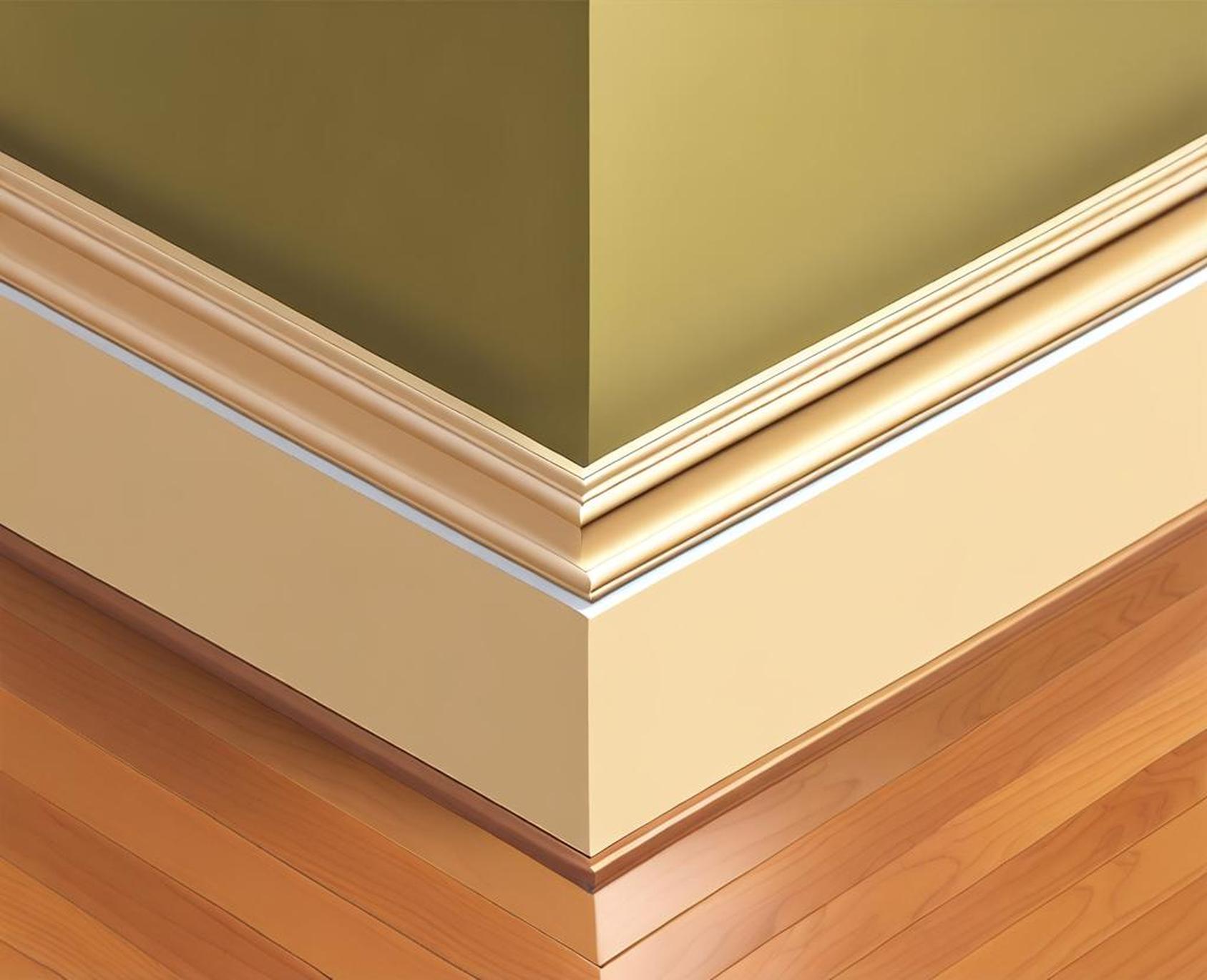

When designing the trim details in your home, you have a choice to make regarding the baseboard corners. Rather than basic 90-degree angles, consider opting for rounded corners instead. Rounded baseboard corners provide a softening effect both visually and physically. They create a more polished, high-end aesthetic compared to harsh right angles. The graceful curves blend beautifully with rooms featuring arched doorways, coved ceilings, and other rounded architectural details.

In spaces with lots of traffic flow or playing children, rounded baseboard corners also reduce bruises and injuries from sharp corner impacts. For safety and visual harmony, it’s easy to see the appeal of cove baseboard corners.

Rounded Baseboard Options

If you’ve decided rounded baseboard corners are right for your room, the next step is choosing how to create them. You have a few different options, each with their own pros and cons regarding difficulty, cost, and customization.

Factory-Made Cove Molding

The easiest route for achieving rounded corners is to simply purchase cove molding trim pieces made specifically for corners. These molding strips come with a curved inside edge designed to provide a finished rounded corner.

Cove corner moldings are widely available at home improvement stores and online retailers. You’ll find them prefabricated from materials like wood, foam, or polyurethane. The installation process is very straightforward, using standard techniques to miter cut the ends and secure the strips in place.

The simplicity of factory-made cove corners makes them a popular choice, but there are some downsides. Size options tend to be limited and getting just the proportions you want can be difficult. Customization is also restricted to what the manufacturer produces. And compared to DIY alternatives, prefabricated cove molding is generally the most expensive route.

Bullnose Corners

For those comfortable with some light woodworking, cutting bullnose corners from standard baseboard trim is another option. With this method, you carefully miter multiple pieces of trim at precise angles to form the rounded inside edge.

Because you can create DIY bullnose corners using basic materials, it is typically more affordable than buying specialty cove products. You also have total control over the exact size and shape based on how each piece is cut. The main drawback is that properly constructing bullnose corners takes more skill, tools, time and labor compared installing pre-made molding.

Plinth Blocks

A third approach for achieving the look of rounded baseboard corners is using plinth blocks. These are decorative blocks secured in each inside corner before installing standard straight baseboard trim around them. Essentially they provide a blank canvas for applying whichever style and size trim you desire.

Plinth blocks offer a high degree of customization for your baseboard corner design. Trims of various materials and patterns can wrap beautifully around the integrated corner curves. But the blocks do require extra construction work and material costs. Unless you have existing decorative blocks available, the effort involved is more than basic cove molding. But likely less work than intricate bullnose corner cuts.

Tools and Materials Needed

If you decide constructing your own bullnose corners is the best fit for your project and skill level, there are some essential tools and materials you’ll need. Gather these before beginning cutting to make the process go smoothly.

- Miter or table saw – For making precise angle cuts

- Carpenter square – To measure cutting angles

- Measuring tape

- Wood glue

- Painter’s tape

- Finish nails

- Wood putty – For filling nail holes

- Sandpaper

- Wood baseboard trim

Safety gear like eye protection, ear protection, gloves and a face mask are also recommended when operating saws and generating sawdust.

How to Cut Bullnose Baseboard Corners

Once you have your materials and tools gathered, the process of measuring, cutting, and securing DIY bullnose corners begins. Follow these key steps for trim pieces that fit together perfectly.

Take Precise Measurements

Precision is critically important when cutting pieces that need to seamlessly intersect. That’s especially true with bullnose corners that rely on all the angle cuts lining up correctly. Take your time with measurements and double check them before making any cuts.

The most vital measurement is the width of the wall section where your center piece will install. You’ll cut the adjoining pieces to overlap that middle section equally on both sides. If calculations are off even a little bit, the joints between pieces will be uneven and gaps will show.

Cut Adjoining Pieces

Mark your measurements on the adjoining pieces and cut them with 22.5 degree angles on the ends. When installed, this angle will let the edges intersect neatly with the center piece. Making test cuts on scrap wood can help you dial in the precision of your saw cuts.

Cut End Pieces at 22.5 Degree Angles

Similarly, the ends of the center piece should be mitered at 22.5 degrees. When all pieces join together, the symmetrical angles create a sharp point to complete the rounded profile.

Assemble the Pieces

With all your trim pieces cut, it’s time to assemble them around the corner. Carefully fitting the five pieces together like a puzzle ensures they form a cohesive bullnose shape free of gaps or uneven sections.

Tape Boards Together in Place

Start by using painter’s tape to hold the pieces in position. Taping them together lets you check alignment, make slight adjustments, and ensure nothing shifts during installation. Take your time aligning the joints perfectly before moving to permanent attachment.

Secure Boards Permanently

Once positioned properly, run a bead of wood glue on the inside edges of the joints. Then nail through the outer edges of the outer pieces into the studs or wall surface. Use wood putty to fill any visible nail holes before finishing.

Finish the Surface

With construction complete, apply your choice of paint, stain, or other protective finish. Lightly sanding before finishing ensures surfaces are smooth and clean for maximum adhesion. Allow finish coats to cure fully before regular use.

- Lightly sand corners

- Paint or stain boards

- Apply protective finish

- Allow to fully cure

Despite best efforts, some projects may still end up with small gaps or uneven joints on the finished corners. Before removing and replacing pieces, try these troubleshooting tips:

- Ensure angle cuts are precise – Recut if needed

- Tape joints tightly before installing

- Use shims if needed for proper alignment

The corners of your baseboard can be looked at with care. Patience and care pays off with gorgeous coved corners that dramatically elevate your room’s style.