Crown moulding is a hallmark of elegant interior design. It adds decorative detail, enhances architectural style, and defines the proportions of a space. However, choosing the right size crown moulding can be confusing. Should you use a larger or smaller size? What measurements matter most? Understanding key dimensions is critical for properly fitting and installing crown moulding.

You’ll learn about the four key measurements – height, width, projection, and thickness. We’ll cover how to precisely measure each dimension, recommend ideal sizes, and provide tips for selecting the perfect moulding. With this detailed reference, you can approach any crown moulding project with confidence.

Height

Definition and Role of Height

The height of a crown moulding refers to its vertical rise when installed. It is measured from the wall up to the highest point of the moulding. Height has a major impact on the overall visual effect. Larger height sizes make a bolder statement and add more decorative emphasis. The height also controls the proportions relative to wall height and ceiling size.

Height Measurement

To measure height accurately, use a tape measure vertically from the wall up to the tallest part of the installed moulding. For mouldings with a spring angle, make sure to account for the tilt and measure to the peak. Record the precise vertical rise.

Height Recommendations

Ideal crown moulding height follows principles from classical architecture. For rooms with 8-foot ceilings, a height between 2-1/2″ to 6″ is recommended, assuming no picture rail moulding. Up to 7-1/2″ can work with a picture rail. For taller 9-foot ceilings, larger sizes from 3″ to 7-1/2″ are preferred, with the addition of a picture rail. Formal spaces can handle more substantial sizes, while lower ceilings often require shorter mouldings.

Width

Definition and Role of Width

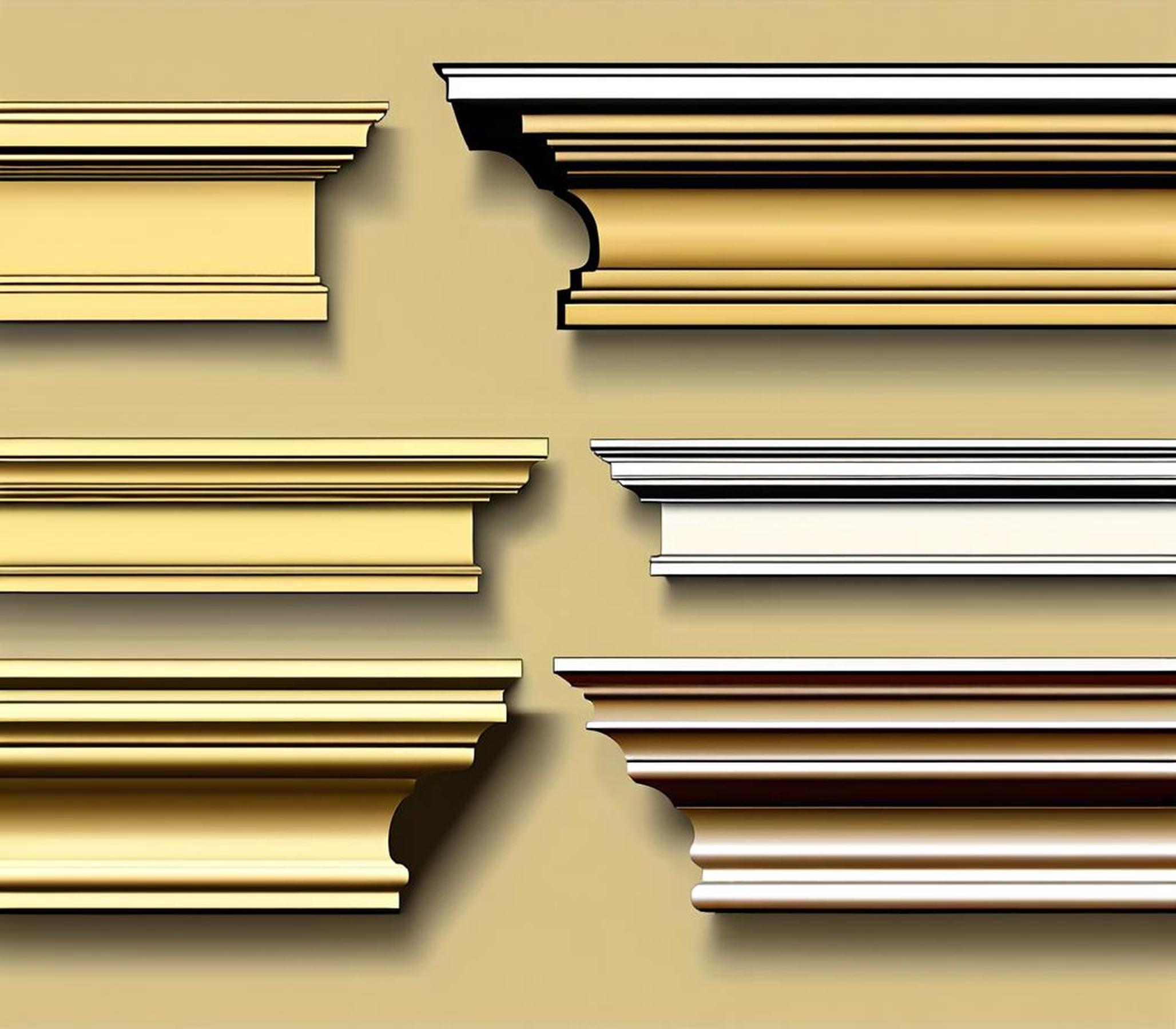

The width refers to the side-to-side, point-to-point dimension of the crown moulding. Measuring across the front face reveals the moulding’s depth and decorative footprint. Wider crown moulding projects more visual weight and casts larger shadow lines. Narrower sizes have a more delicate presence.

Width Measurement

Measurement of the moulding width is straightforward. Use a tape measure across the front face, from one edge to the other. This point-to-point method gives the true width and is consistent with other trim carpentry techniques.

Typical Width Ranges

In residential settings, crown moulding widths often range from 2-1/2″ to 4″. Rooms with higher ceilings or larger square footage can sometimes accommodate widths up to 6″. Matching existing trim profiles or architectural style typically guides width selection.

Projection

Definition and Role of Projection

The projection refers to how far the crown moulding extends horizontally from the wall when installed. Greater projection adds more visual weight and dimension. More subtle mouldings project less from the wall.

Projection Measurement

To determine projection, use a tape measure horizontally from the wall surface to the furthest point on the edge of the installed moulding. Make sure the moulding is level to get an accurate reading.

Projection Guidelines

Ideal projection proportions follow classical architecture principles. In general, the projection dimension is about half the height. For example, a 5″ crown would project around 2-1/2″ from the wall. The exact ratio can vary depending on factors like ceiling height and personal preference.

Thickness

Definition and Role of Thickness

The thickness refers to the top-to-bottom, point-to-point depth of the moulding. Thicker mouldings have more physical presence and visual weight. They also provide greater structural strength and durability.

Thickness Measurement

Measuring thickness uses the same simple point-to-point method as for width. Use a tape measure vertically across the moulding section to determine depth from top to bottom. Consistency in trim carpentry measurement technique is key.

Thickness Considerations

Thicker mouldings around 3/4″ to 1″ are sturdier and less prone to damage or warping. However, thicker material costs more. Finding the right balance depends on budget, supplier availability, and the need for durability. Architectural style also influences ideal thickness.

Choosing the Right Size

Room Height and Proportions

When selecting crown moulding, consider the room’s ceiling height and overall spatial proportions. Taller ceilings call for larger moulding heights, while lower ceilings demand more subtle sizes. The goal is pleasing room proportions, not just oversized mouldings.

Formal vs. Casual Settings

For formal living rooms or dining rooms where elegance is key, larger crown mouldings make sense. They create an upscale ambiance. But for secondary casual spaces like bedrooms, smaller moulding maintains the comfortable feel.

Matching Other Trim

For a cohesive effect, match new crown moulding to existing baseboard or window trim heights. Repeat moulding widths throughout the space for visual harmony. Consistent design elevates the overall style.

Understanding the key measurements – height, width, projection, and thickness – takes the guesswork out of choosing crown moulding dimensions. Follow the measurement, sizing, and installation tips outlined above to demystify the process. Our guide equips you with the knowledge to select moulding with perfect proportions for any space. For additional resources, use our handy crown moulding calculators and dimension charts.

With the right know-how, achieving beautiful, well-sized crown moulding is simple. Let us know if you have any other questions!

The impact of crown molding on acoustics

While primarily an aesthetic element, some studies have shown crown molding can also improve room acoustics. Moldings with dense materials and profile shapes that scatter sound waves can reduce echoes and reverberation. This acoustic benefit is notable for rooms with hard flooring and sparse furniture, which can cause distracting echo issues.

For example, one study published in Building Acoustics tested various trim profiles’ impact on sound absorption. Some ornate, curved crown moldings provided measurable improvements by diffusing sound energy. The effect stems from the complex shape reducing distinct echo reflections. However, very lightweight foam moldings showed little acoustic influence.

The relationship between crown molding and lighting

Crown molding can directly impact light distribution and ambiance. The molding’s shadow lines, reflection, and visual prominence all interact with lighting. Designers carefully consider lighting and crown molding together to create an integrated aesthetic.

For instance, uplighting can accentuate a bolder crown profile, while downlighting may overwhelm a subtle molding. Indirect ceiling lighting reduces shadows to spotlight the molding itself. Wall sconces paired with crown molding frame the space beautifully. Thoughtful lighting brings out the molding’s textures and dimensions.

The role of crown molding in sustainability

Sustainability in construction and design is an increasing priority. Eco-conscious molding options like recycled plastic styles with no VOCs have gained popularity. Some manufactures even use recycled paper or organic bamboo materials.

Certain moldings can also boost energy efficiency. Solid wood moldings provide additional insulation value versus drywall alone. Well-sealed trim may help reduce air leaks and heat transfer. However, sustainability depends on the full life cycle, including factors like location of manufacturing.

Crown molding has special cultural and historical significance. It first gained prominence in European architecture from ancient Greek and Roman traditions. Intricate molding emphasized wealth and status. Later, American colonial styles adopted simplified crown profiles suited to available materials.

Today, crown molding still connotes formality, tradition, and craftsmanship. Its applications span palaces, churches, libraries, theaters, and upper-class estates. Crown molding endures as both architectural heritage and a distinctive aesthetic style layering elegance into any space.