Upgrading home electrical service can be confusing. With so many wire sizes and types available, how do you ensure you choose correctly? We’ll walk through the key factors in selecting the proper wire for 100-amp capacity, from wire types to environmental considerations.

By understanding guidelines for wire size, amperage capacity, voltage drop, and safety specifications, you can make an informed decision whether you’re installing wiring yourself or getting professional estimates.

Wire Gauge Size Standards

Wire gauge refers to the diameter or thickness of the conductor metal inside the wiring. In the US, gauge size is denoted by the American Wire Gauge (AWG) system. The larger the AWG number, the smaller the wire – for example, a #6 AWG wire is thicker than a #10 AWG wire.

For typical residential wiring, common sizes range from #14 AWG for 15-amp branch circuits up to #4 or #2 AWG for a 100-amp service panel. The larger wire diameters used for 100 amps allow for safer transmission of more current.

Why Wire Gauge Matters

Higher amperage capacity requires thicker wires to:

- Prevent overheating and reduce fire risks

- Minimize voltage drop over long wire runs

- Withstand extremes of temperature, moisture, etc.

Using wires that are too small can lead to unsafe conditions. Consulting electrical code books and load calculations provides recommended guidelines per application.

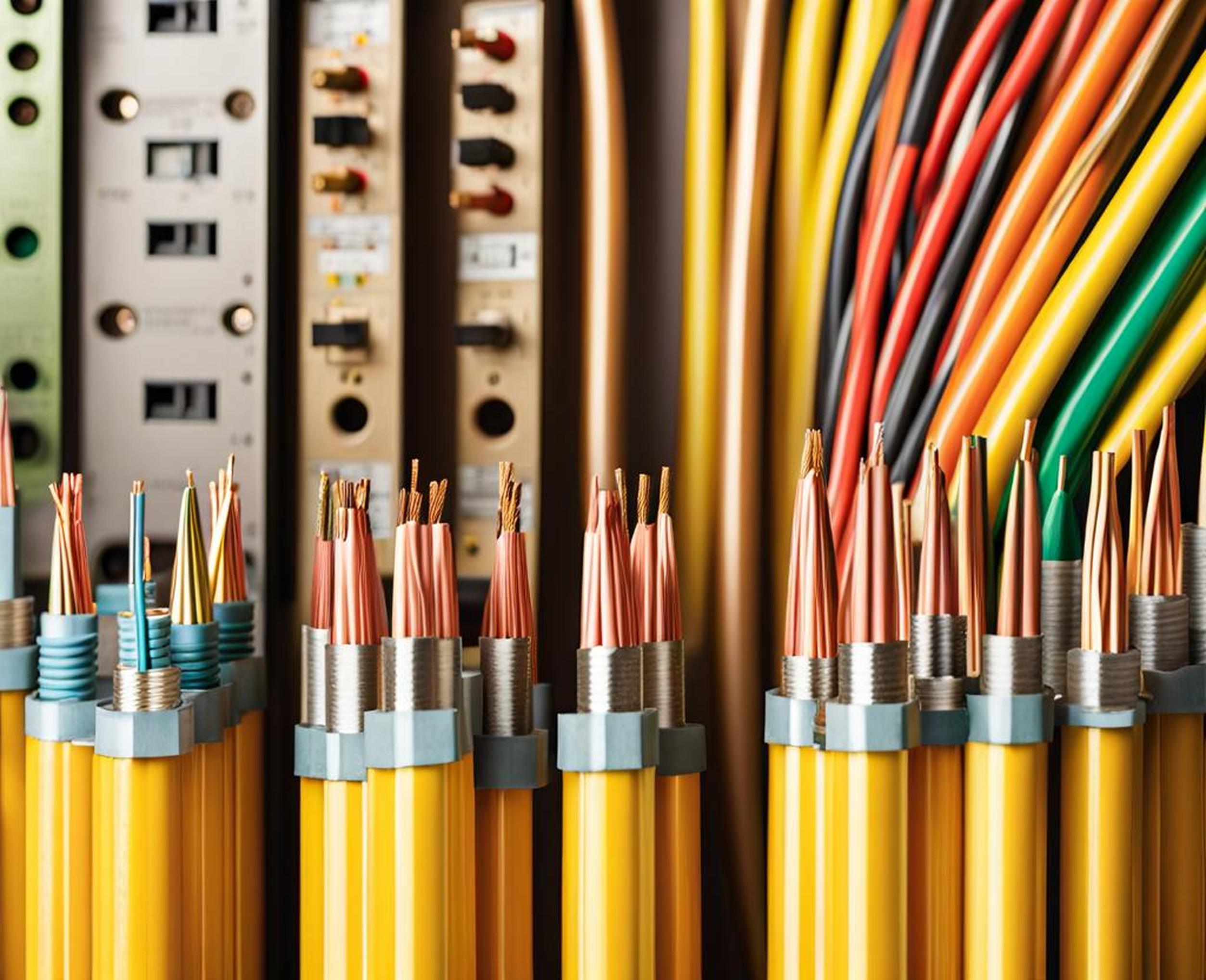

Wire Types for 100 Amps

Copper Wire

Copper wiring is the preferred choice due to its high conductivity and durability. While more expensive than aluminum, copper is safer and easier to work with. It also has better ampacity for the same gauge size versus aluminum.

For 100-amp service, common copper wire sizes are:

- #4 AWG for shorter runs up to 50 feet

- #2 AWG for longer runs up to 100 feet

Aluminum Wire

Aluminum is lighter in weight and lower in cost, but has some downsides to consider:

- More prone to corrosion and expansion/contraction

- Requires special safety precautions for terminations

- Reduced ampacity – larger sizes needed than copper

If choosing aluminum, use one wire gauge size larger than copper. For example, for longer wire runs, use #1 instead of #2 AWG. Consult local building codes for restrictions.

Other Options

Copper-clad aluminum wire combines a copper exterior around an aluminum core. This offers the conductivity of copper along with easier handling and better terminations compared to all-aluminum wiring.

Key Factors in Choosing Wire Size

Electrical Load Demands

The wire size must suit the electric current draw of all lighting, equipment, and devices powered by the service panel now and into the future. Evaluate:

- Existing lighting fixtures, outlets, major appliances

- Heating/cooling systems, well pumps, pool heaters

- Capacity for additional circuits in unfinished spaces

- Potential electric vehicle charging needs

In some cases, separate sub-panels may be warranted to provide capacity for additional loads.

Wire Run Length

The distance the wire travels from the electrical panel to devices affects the choice of size due to voltage drop. Voltage drop increases with:

- Higher current draw

- Smaller diameter wires

- Longer wire run distances

Larger wire sizes compensate for voltage drop over long runs. For example:

- Up to 50 feet: #4 AWG copper

- 50 to 100 feet: #2 AWG copper

Environmental Conditions

Both indoor and outdoor wires need proper insulation for the conditions. PVC insulation suits dry indoor applications. Use moisture-resistant THHN wire where dampness is a concern.

In hot attics and outdoor runs, high temperatures also come into play. Wire capacity (ampacity) decreases when operating at elevated temperatures. Overheated wires can degrade insulation and pose fire risks. Use wiring rated for both wet and hot environments as needed.

Local and Regional Codes

While the National Electrical Code (NEC) sets minimum capacity guidelines, your local Authority Having Jurisdiction (AHJ) may require specifics above these. Research regional amendments for:

- Acceptable wire types and sizes

- Derating capacity for temperature

- Conduit fill requirements

Factoring in all code directives ensures your wiring meets regulations and provides safe, future-proof capacity.

Wire Size Recommendations for 100 Amps

Short Wire Runs

Need to connect a 100-amp sub-panel near the main panel? For runs less than 50 feet, #4 AWG copper wire allows for the 100-amp circuit capacity.

Copper is preferred over aluminum for short, easy pulls. Ensure insulation (THHN/THWN) suits environmental needs.

Long Wire Runs

For 100-amp service feeding a main household panel, the most common minimum size is #2 AWG copper or copper-clad aluminum wire. The larger diameter handles increased current over distances up to 100 feet without excess voltage drop.

When using all-aluminum, choose #1 AWG or larger to match ampacity of #2 AWG copper. Apply wire lubricant for difficult pulls.

Underground Wiring

Running wiring underground has additional considerations of using larger conduit for wire protection, dealing with moisture penetration, and facilitating difficult cable pulls.

Common underground wiring choices include:

- Individual THHN/THWN-2 conductors in nonmetallic conduit

- UF cable (Underground Feeder)

- XHHW aluminum conductors for longer runs

Consult local codes for specifics on waterproofing, conduit size and material, burial depth, and more based on your installation environment.

Working With Electricians

Upgrading home electrical service may require permits and inspections to meet code. Hiring a licensed electrician ensures:

- Correct load calculations to size wiring

- Precise installation methods and terminations

- Required bonding, grounding, GFCI and AFCI protection

- Final inspection compliance for safety

Questions to Ask Electricians

When getting estimates for 100-amp service upgrades, electricians should evaluate your existing electrical, space for expansion, and environmental factors at your site. Prepare questions ahead of time:

- What wire size do you recommend and why?

- Do I need copper or is aluminum acceptable?

- How far is the run distance from my main panel?

- How much conduit or protective material is included?

- What specific regional electric codes apply?

Red Flags

Avoid electricians who:

- Don’t discuss wire types and sizes for your specific loads

- Lack knowledge of NEC guidelines and local amendments

- Quote low prices by skimping on materials or safety factors

This often leads to problems or code violations down the road.

Now that you know more about choosing the right wire for 100 amps, you’re prepared to either install it yourself or speak intelligently with electricians. Keep the following in mind:

- Accurately assess your current and future electric loads

- Mind wire run length and conditions to size wires appropriately

- Choose suitable wire material for ampacity and location

- Consult regional codes and permit authorities for approvals

As you upgrade wiring, panels, and circuits, don’t forget updated overcurrent protection and grounding. Installing GFCI and AFCI breakers reduces shock and arc-fault dangers.

By proactively planning your home’s power infrastructure, you ensure adequate, safe electrical capacity well into the future.