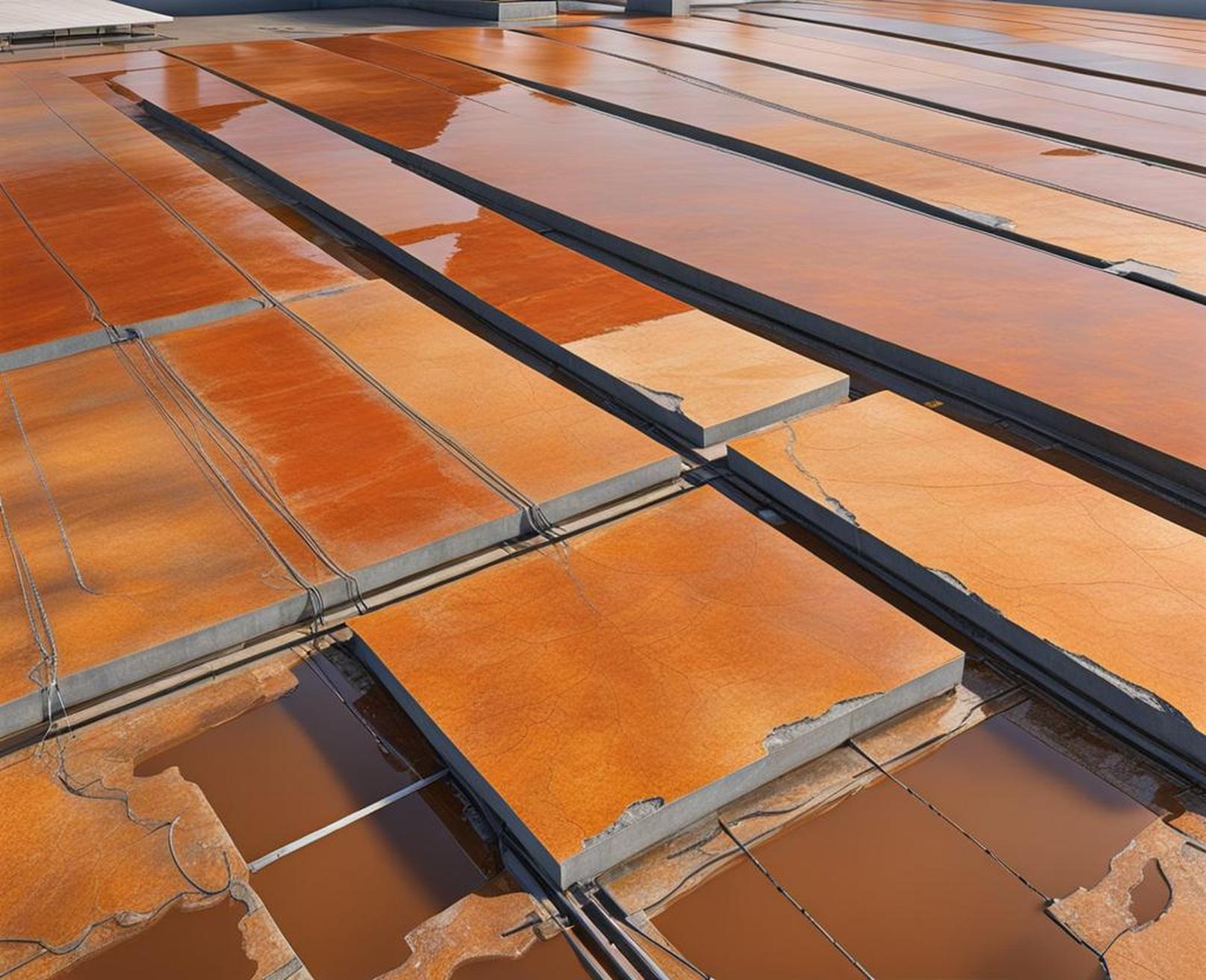

In recent years, there have been several concerning incidents involving the failure of post-tension (PT) concrete slabs. These failures have occurred both during construction and in existing buildings, raising alarm bells across the industry. When a post-tension slab fails, it can lead to a catastrophic collapse and poses a major safety risk. Understanding why these failures occur is crucial so that we can prevent them in the future.

Causes of Post-Tension Slab Failure

Post-tension slab failures can occur due to a variety of factors, including:

Overstressing Cables

The cables inside a post-tension slab provide compressive force that improves the slab’s strength and stiffness. However, if these cables are overstressed during construction, it can cause them to rupture or fail prematurely. There are a few ways overstressing can occur:

- Improper calibration of jacking equipment

- Over-estimating the slab’s capacity

- Errors in calculating required cable force

When cables are overstressed beyond their capacity, the consequences can be catastrophic. The cables may snap or tear out of the anchorage, leading to immediate structural failure.

Low Concrete Strength

Achieving adequate concrete strength is vital for a durable post-tension slab. However, low strength concrete can result from:

- Poor quality control during batching and mixing

- Inadequate curing procedures

- Premature formwork removal

- Cold weather concreting issues

Concrete that does not reach its specified design strength can lead to cracking, deformation, and decreased load capacity in the slab. This severely compromises the slab’s structural integrity.

Structural Design Issues

Flaws in the structural design of a post-tension slab can also precipitate failure:

- Inadequate reinforcement

- Improper post-tensioning cable layout

- Design errors related to loads and structural analysis

These issues set the stage for failure right from the beginning. Without an accurate understanding of the loads and stresses involved, the slab cannot be designed to properly withstand these forces.

Investigating the Root Causes

When a post-tension slab failure occurs, it is critical that a thorough investigation is conducted to determine the root cause. An expert team should be assembled including:

Structural Engineers

Structural engineers are essential for analyzing the slab design and identifying any flaws or inadequacies. They can assess whether the structural analysis properly accounted for loading conditions and if the reinforcing and post-tensioning layout was appropriate.

Geotechnical Engineers

Input from geotechnical engineers is needed to understand the soil-structure interaction. They can determine if issues like differential settlement of the supporting soil contributed to slab cracking and failure.

Materials Scientists

Materials scientists help evaluate material defects that may have played a role. For example, improper concrete curing or delayed grout injection could have impacted material properties and led to premature failure.

Together, this team can perform in-depth analysis into the design, construction, maintenance, and materials aspects to get to the bottom of what went wrong and where the failure originated.

Enhancing Design Practices

The findings from the root cause investigation should inform enhancements to design practices for post-tension slabs moving forward:

Using More Robust Materials

Using higher strength concrete and steel can provide more durability and resilience. For example, improving concrete compressive strength from 3000 psi to 4000 psi increases the factor of safety.

Improving Construction Techniques

Refined construction techniques like improved consolidation of concrete, slower formwork removal, and staged post-tensioning can enhance constructability and prevent failures.

Developing Better Computational Design Methods

State-of-the-art computational methods like finite element analysis help model slab behavior under different loads and conditions. This enhances design accuracy.

Improving Construction Practices

Paying close attention to construction practices in the field is also crucial:

More Detailed Instructions and Guidelines

Providing comprehensive instructions and checklists helps minimize errors in construction sequencing and quality control.

Implementing Rigorous Quality Control

Enhanced QA/QC testing of concrete strength, cable stressing, and other key processes is needed to prevent flaws.

Better Monitoring and Maintenance

For existing structures, robust monitoring and maintenance helps detect issues early:

More Frequent Inspections

Inspections at least every 5 years check for cracking, deflection, and other signs of distress.

Regular Cable Testing

Tension force in cables should be routinely tested to identify any deterioration or loss of prestress.

Advanced Monitoring Methods

Technologies like digital image correlation can precisely monitor slab deformation and crack propagation.

Communication and Collaboration

Preventing post-tension slab failures requires effective communication and collaboration between all parties:

Detailed Project Plans with Stakeholder Input

Project plans should be comprehensive, with requirements and expectations clearly defined after eliciting input from designers, contractors, and owners.

Effective Communication Channels

Open channels for raising concerns and resolving problems are essential throughout design and construction.

Alternative Solutions

In some cases, post-tension slabs may not be the optimal foundation solution:

Exploring Alternative Foundations

Raft or piled foundations may be better suited to poor soil conditions that can undermine slab integrity.

When to Consider Alternatives

Significant differential settlement, aggressive chemical exposure, and other challenging site factors warrant consideration of other foundation options.

Repair and Replacement Methods

Repairing damaged post-tension slabs can be complicated. Better solutions are needed:

Developing Better Methods

Minimally invasive techniques like supplemental cable reinforcement can restore structural capacity while limiting disturbance to residents.

Minimally Invasive Techniques

Methods like injection repair of damaged cables avoids the cost and disruption of full slab replacement.

Cost-Effective Approaches

Prioritizing affordable repair solutions helps facility owners address issues before they become unmanageable.

Post-tension slab failures can result from a range of factors, including issues with design, construction, materials, and maintenance. Performing thorough investigations and enhancing practices across the board will help reduce these types of incidents. By proactively addressing areas like design methodology, construction techniques, quality control, monitoring, and communication, we can ensure post-tension slabs serve safely and effectively throughout their service life.